The 8-Minute Rule for Plant Conveyors And Systems

Table of ContentsHow Plant Conveyors And Systems can Save You Time, Stress, and Money.The Buzz on Plant Conveyors And SystemsThe 8-Second Trick For Plant Conveyors And SystemsAll about Plant Conveyors And Systems3 Easy Facts About Plant Conveyors And Systems Shown

Safety: Conveyor systems are controlled by the Occupational Security and Wellness Administration (OSHA) as well as must meet government safety and security needs. All conveyor manufacturers are mindful of the laws and stick to them.Belt Conveyors Belt conveyors are one of the most typical as well as simplest form of conveyor and can have variable rates. They have a moving belt that rests on a steel framework that supports the belt and also the products being relocated. Ones that have a supporting structure below are described as sliding style.

Gravity Roller Conveyors Gravity roller conveyors have a set of similarly spaced rollers attached to a side frame. If a gravity roller conveyor is tilted or placed on an angle, products move by gravity.

Chain Conveyors Chain conveyors can have 2 or several sets of chains that make contact with all-time low of things to be moved - Plant Conveyors and Systems. The products rest on the chains as they are relocated. Chain driven conveyors are excellent for products with uneven bottom surface areas or ones that are very heavy.

Plant Conveyors And Systems Can Be Fun For Everyone

Because of the types of items chain conveyors move, they operate very gradually. Motorized Roller Conveyors Motorized roller conveyors utilize motors, positioned along the conveyor framework, to power equally spaced rollers. The layout is comparable to a gravity conveyor with the addition of motors. The number of electric motors is dependent on the load to be relocated as well as the overall design of the system.

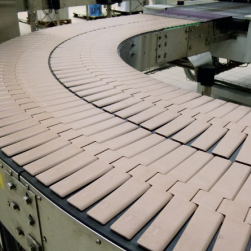

In some systems, there is a sensing unit that starts as well as stops the electric motor to prevent pieces obtaining packed with each other. Slat Conveyors Slat conveyors have the exact same layout as chain conveyors with level slats attached to the chain. Somehow, they resemble belt conveyors with slats changing the belt.

The enclosure safeguards the track from wear and also makes it simpler to place bends and also contours in the system. Open Track Conveyors - Open up track conveyors do not cover the track and also use I beams as the track. They are simple to set up and excellent for lengthy straight configurations. Chain Overhead Conveyors - Chain expenses conveyors utilize a constant powered chain that leaves a track.

In various other styles where necklaces are not used, pusher dogs might be utilized to move trolleys along a 2nd track placed beneath the chain track. This kind of system is described as power and complimentary. Monorail Conveyors Monorail sharing systems have service providers to relocate products as well as are suitable for usage over cross countries.

10 Easy Facts About Plant Conveyors And Systems Explained

Monorail conveyors take advantage of the room over the manufacturing area. In some layouts, the carriers reduced to the level of production as well as then go up, out of the method. Power as well as Free Conveyors Power as well as free sharing systems are designed to move components via the production and also assembly procedure.

They quit at each terminal to be dealt with and afterwards move on. Power and complimentary systems are an unique type of overhead communicating system. The special style of power and check it out complimentary systems allows a product to be buffered along the communicating course, beginning and stop immediately, and also are extremely flexible and also adjustable.

Upside down Conveyors Inverted conveyors are floor installed and also can be utilized as power and also free conveyors. They normally have a drive system that does not involve a belt or chain. Paternoster Conveyors Paternoster conveyors are a vertical conveying system that utilizes equal spaced tons service providers attached to a chain drive, which moves in a constant loop (Plant Conveyors and Systems).

About Plant Conveyors And Systems

The chain can bending along the straight axis enabling it to make horizontal turns and is capable of making upright contours. The numerous sorts of spins and also turns a COE makes enables it to be much more flexible than typical chain driven conveyors. Skid Conveyor Skid conveyors are another kind of flooring placed conveyor that moves items on components that have actually longitudinal runners called skids with travel being longitudinally as well as transversely.

Skid conveyor systems are valued for the effectiveness and also quiet mode of transport. The variants in skid conveyor systems are because of the numerous elements as well as control systems that can be included. Rubbing Conveying System A rubbing communicating system uses a motor to drive a rubbing wheel made from non metallic product to develop driving pressure.

Friction communicating systems are a risk-free option to power and also complimentary systems with the major advantage of running cleaner and quieter. They have an adaptable layout, system building, simple speed changing, can conveniently be broadened, as well as low my explanation general expense. The primary objective for friction conveying systems is to help with procedures that have a high production rate.

The Ultimate Guide To Plant Conveyors And Systems

Assistance System: The assistance system permits the belt to move efficiently. It is especially made to hold the relocating material without drooping.